Eps Cement Sandwich Panel is a kind of lightweight Energy-saving wall material taking reinforced calcium silicate or cement calcium silicate Board as face panel,cement,eps,fly ash as core forming by one time compound.

Why choose our compound sandwich panel?

| 1 | green | 100% free of harmful substances and are of A non-radioactive products, standard GB6566-2001. | |||||||||||

| 2 | lightweight economic | The volume-weight only 750-800kg/m3 , the weight of 75mm thickness ZJT board is 60kg/m2, equal to 1/6 of brick weight, 1/7 of 120mm thickness masonry. | |||||||||||

| 3 | increase valid space | the thickness of ZJT wall decreases 85mm by using 75mm thickness ZJT boards. Thus, valid space increases 1/m2 per 11.8mm. in other words, it can increase 6/m2 per 100/m2 . | |||||||||||

| 4 | moistureproof waterproof | will keep dry and leave no stains. During humid days, the boards will not condense water either. suitable to be installed in such wet areas as kitchens, bath rooms, basements because of its moistureproof and waterproof. | |||||||||||

| 5 | fireproof | Fireproof limit of ZJT boards is more than 4 hours and does not emit toxic gases under 1000 degree. The nonflammable performance reaches national A-class standard. | |||||||||||

| 6 | heat insulation | ZJT board is composed of special material to keep heat and thermal within a favorable condition. At same time, the ZJT boards are able to adjust moisture automatically and keep moisture at a balance level. | |||||||||||

| 7 | sound insulation | The raw materials of ZJT boards have good performance in sound insulation. ZJT board with 90mm thickness gains sound insulation of 42dB. | |||||||||||

| 8 | walls can be nailed and grooved | ZJT board can be grooved to have conductor arrangement or nailed to hang heavy object. The surface of ZJT board is smooth enough to make finisher processing directly with tile, wall trim and so on. | |||||||||||

| 9 | good integration | By using steels at the joints, the strength of walls is high enough to do partition in large story height and long span structures and it anti-seismic performance is several times higher than masonry. | |||||||||||

| 10 | easy and fast construction | It can be cut to adjust length and width at will. The process of installation is easy and fast, without the need of plastering. | |||||||||||

Raw Material and Feature of ZJT sandwich panel

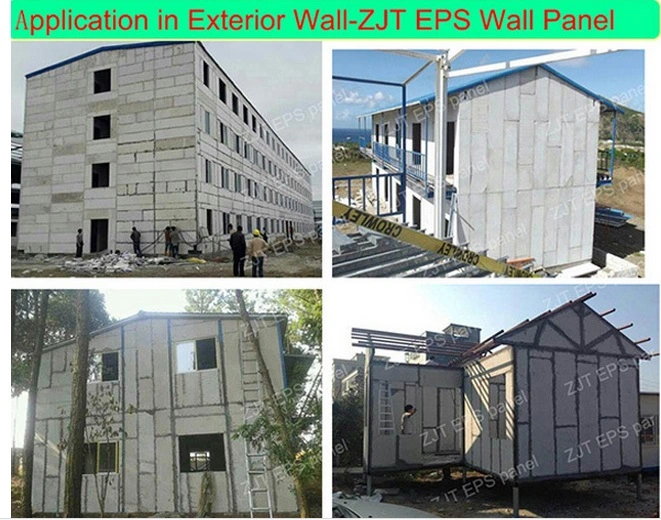

Application of ZJT wall panels

Installation Process of Wall Panel for Prefab House

1 Release and lift the board: The baseline of the projectile in the wallboard installation is perpendicular to the bottom of the board or the bottom of the beam to ensure that the wall panel is straight. A 1.49 square wall panel can be transported freely.

2 Saw board: According to the requirements, the machine can be arbitrarily cut and the width and length of the wall board can be adjusted to reduce the wall panel loss rate.

3 sizing: Use cement and medium sand (1:2) and add construction glue to make a paste. First use the water to brush the concave and convex grooves of the wet wallboard, then apply the polymer mortar to the concave and convex grooves of the wallboard and the floor baseline. .

4 Loading the board: Move the wall board with the good mortar to the loading position, raise the baseline position up and down, and use the iron shovel to lift the wall board from the bottom to make the board and the board tight.

5 In place: Firmly press the wallboard to squeeze the mortar out of the joint to ensure that the mortar is full and temporarily fix it with a wooden wedge.

6 Correction: Check the straightness of the flatness and verticality of 2 meters: the iron shovel adjustment, and then use the wooden wedge and the steel bar to fix it up and down.

7 Stapling: The connection between the wallboard and the wallboard must be anchored with Φ6×200mm steel bars inclined at 45°.

8 Fixing: After correcting with both sides of the 30×30mm wooden wedge, drill the hole at the 45° angle with the impact drill at the 45° angle, and then anchor with Φ6×200mm steel.

9 Grouting: Install the calibrated wallboard with cement mortar (1:2) and add the construction glue to adjust the seam between the upper and lower seams and the board to the polymer paste, and pull out the wooden wedge. The mortar is filled.

10 Slotted embedding pipe: If you want to embed dark pipeline, switch box, etc., you can install it with impact drill or portable electric saw cutting slot, and then fill it with mortar polymer after installation.

11 Door frame: The door frame can be covered with a splint directly on the wall panel, anchored with iron nails and the wall, and decorated with a cover.

12 Plastering Paint: Finally, apply the top coat. If the tile is attached, there is no need to scrape the ash, and the tile can be directly attached to the wallboard with the cement slurry, or the wallpaper, the wood slab, etc. can be directly pasted.

Contact Information