Product name :Exterior wall use Fibre cement backer board fireproof

1. Introduction

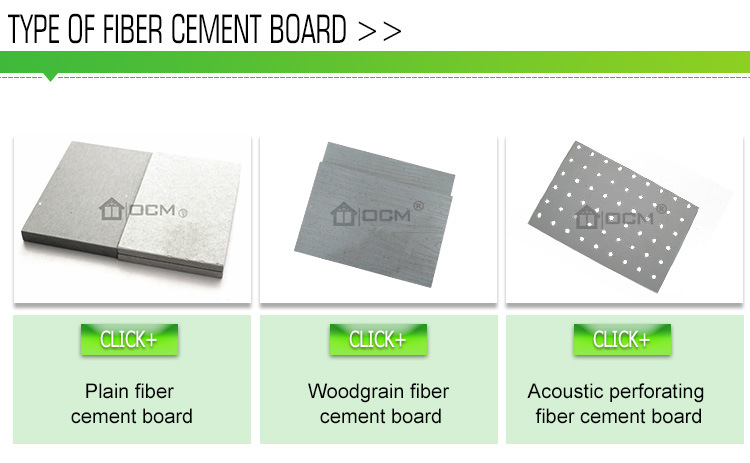

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibers and fillers. It is 100% free from asbestos, sepiolite, inorganic fibers or formaldehyde. The board is versatile and suitable for general use of internal and direct weathering applications when used in conjunction with external grade texture finish or other surface coating in new construction or refurbishment projects. It is an economical, non-combustible building board material to replace traditional concrete / clay block or cement-bonded particle board for the construction of non-load bearing elements. Unlike most plywood, cement-bonded particle boards, gypsum boards or magnesium boards, fiber cement board is light weight, strong, moisture resistant, will not warp, swell or decay in wet area.

2. Key benefits

Fire Resistant: 'Class A' (0 Flame / 0 Smoke)

Noncombustible: (10-minute duration)

Mold/Fungus Resistant: Does not support mold/fungus growth

Moisture Resistant: Resistant to weather, freeze/thaw & standing water

Termite/Vermin Resistant: Provides no food value to insects/vermin

Impact & Abuse Resistant: Made from durable Portland Cement

Acoustic Performance: Has a density of 77lbs/ft3

Workability: Installs quickly using standard carpentry tools and equipment

Dimensionally Stable: Exhibits excellent resistance to dimensional changes when exposed to variations in temperature & moisture

Environmentally Friendly: Composed of 28% post-industrial wood content, contains no added HCFC's or VOC's, no added formaldehyde or asbestos, reduces materials on the job

3. Physical properties

1) Thermal Conductivity ≤ 0.45 W/(m. K)

2) Water Absorption; ≤ 36%

3) Water Contain; ≤ 10%

4) Swelling Rate; ≤ 0.25%

5) Freezing resistance; On opening and clapping

6) Watertightness; O water formed

7) Non-combustibility; Form to GB8624 Class A

4. Installation

Fiber cement board can be easily cut on site by using a sharp fine-toothed panel saw or hacksaw. Place tiles face down on a clean, smooth surface for cutting. When power sawing and sanding, nuisance dust levels may need to be controlled. In order not to damage the finishes of Fiber cement tiles; It is recommended that the installer should wear gloves to lay the tiles. For better acoustic and thermal insulation performance, a layer of mineral wool or fiberglass can be laid on top of the Fiber cement tiles or panels.

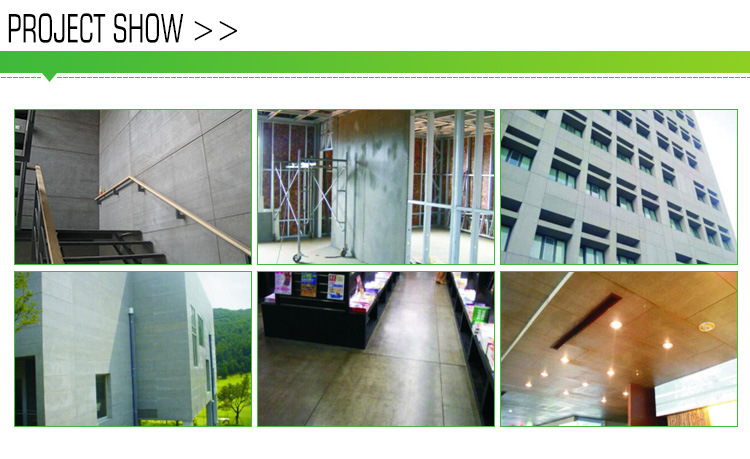

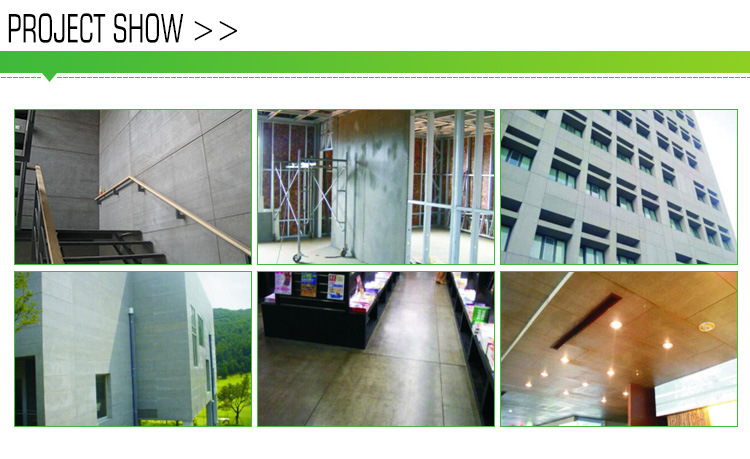

5. Application of cement backer board fireproof

Fiber cement boards can be used from ceiling to flooring and everything in between

1) Office,

2) Libraries,

3) Hospitals,

4) Entertainment buildings

5) Hotels and restaurants,

6) Exhibition centers

7) Washrooms and kitchens

8) Galleries,

9) Indoor swimming pools

6. Packing and cement backer board fireproof

7. Company information

8. FAQ

1.What is your delivery time ?

15-20 days after down payment

2.What's your payment terms?

30% deposit by TT ,balance after B/L or irrevocable L/C

3.Can customized size as our reques?

Yes,we can cut any size as request

4.What's your company production capacity?

We can produce 8000sqm (10mm) per day

5.What's your MOQ,can we order mixing different size ?

Yes ,MOQ 100pcs and mixed loading also acceptable

1. Introduction

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibers and fillers. It is 100% free from asbestos, sepiolite, inorganic fibers or formaldehyde. The board is versatile and suitable for general use of internal and direct weathering applications when used in conjunction with external grade texture finish or other surface coating in new construction or refurbishment projects. It is an economical, non-combustible building board material to replace traditional concrete / clay block or cement-bonded particle board for the construction of non-load bearing elements. Unlike most plywood, cement-bonded particle boards, gypsum boards or magnesium boards, fiber cement board is light weight, strong, moisture resistant, will not warp, swell or decay in wet area.

2. Key benefits

Fire Resistant: 'Class A' (0 Flame / 0 Smoke)

Noncombustible: (10-minute duration)

Mold/Fungus Resistant: Does not support mold/fungus growth

Moisture Resistant: Resistant to weather, freeze/thaw & standing water

Termite/Vermin Resistant: Provides no food value to insects/vermin

Impact & Abuse Resistant: Made from durable Portland Cement

Acoustic Performance: Has a density of 77lbs/ft3

Workability: Installs quickly using standard carpentry tools and equipment

Dimensionally Stable: Exhibits excellent resistance to dimensional changes when exposed to variations in temperature & moisture

Environmentally Friendly: Composed of 28% post-industrial wood content, contains no added HCFC's or VOC's, no added formaldehyde or asbestos, reduces materials on the job

3. Physical properties

1) Thermal Conductivity ≤ 0.45 W/(m. K)

2) Water Absorption; ≤ 36%

3) Water Contain; ≤ 10%

4) Swelling Rate; ≤ 0.25%

5) Freezing resistance; On opening and clapping

6) Watertightness; O water formed

7) Non-combustibility; Form to GB8624 Class A

4. Installation

Fiber cement board can be easily cut on site by using a sharp fine-toothed panel saw or hacksaw. Place tiles face down on a clean, smooth surface for cutting. When power sawing and sanding, nuisance dust levels may need to be controlled. In order not to damage the finishes of Fiber cement tiles; It is recommended that the installer should wear gloves to lay the tiles. For better acoustic and thermal insulation performance, a layer of mineral wool or fiberglass can be laid on top of the Fiber cement tiles or panels.

| Size (mm) | Thickness (mm) | Weight (Kg) | Edge profile | Application |

| 1200*2400 | 4 | 18 | square-cut edge | internal cladding |

| 1220*2440 | 18.61 | |||

| 1200*2400 | 6 | 27 | square-cut edge/Recessed edge | internal/external ceiling |

| 1220*2440 | 27.91 | |||

| 1200*2400 | 8 | 36 | square-cut edge/Recessed edge | internal partition/external wall cladding/ wet area and tile backing /floor underlay |

| 1220*2440 | 37.21 | |||

| 1200*2400 1220*2440 | 9,10 | 40.5 | square-cut edge | external wall cladding/wet area and tile backing /floor underlay |

| 41.86 | ||||

| 45 | ||||

| 46.51 | ||||

| 1200*2400 | 12 | 54 | square-cut edge/Recessed edge | external wall cladding/wet area and tile backing /floor underlay |

| 1220*2440 | 55.82 | |||

| 1200*2400 | 15 | 66.27 | square-cut edge | internal partitions with special requirements /elevated floor |

| 1220*2440 | 68.5 | |||

| 1200*2400 | 18 | 79.52 | square-cut edge | internal partitions with special requirements /elevated floor |

| 1220*2440 | 82.2 | |||

| 1200*2400 | 20 | 88.36 | square-cut edge | internal partitions with special requirements /elevated floor |

| 1220*2440 | 91.33 |

5. Application of cement backer board fireproof

Fiber cement boards can be used from ceiling to flooring and everything in between

1) Office,

2) Libraries,

3) Hospitals,

4) Entertainment buildings

5) Hotels and restaurants,

6) Exhibition centers

7) Washrooms and kitchens

8) Galleries,

9) Indoor swimming pools

6. Packing and cement backer board fireproof

7. Company information

8. FAQ

1.What is your delivery time ?

15-20 days after down payment

2.What's your payment terms?

30% deposit by TT ,balance after B/L or irrevocable L/C

3.Can customized size as our reques?

Yes,we can cut any size as request

4.What's your company production capacity?

We can produce 8000sqm (10mm) per day

5.What's your MOQ,can we order mixing different size ?

Yes ,MOQ 100pcs and mixed loading also acceptable