Newly Low-Cost Construction Material High-Quality EPS Cement Wall Board/Panels

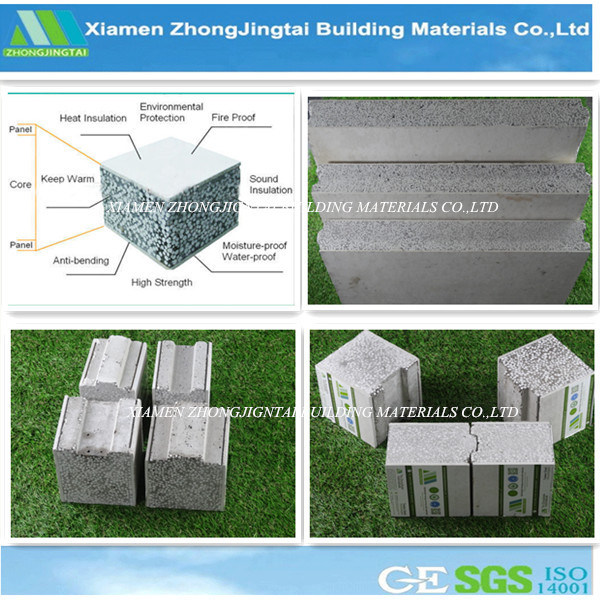

Product Composition

Surface : Calcium Silicate Board

Interior filling materials: EPS / cement / fly ash / sand / additives

Product Advantages

1. Energy saving / Green / Environmental friendly

2. Durable

3. Strong Hanging Force

4. Fireproof

5. Waterproof/ Moisture proof

6. Sound Insulation

7. Quakeproof

8. Convenient for wire grooving and Slotting

9. Rapid Installation

10. Dry working

11. Excellent Surface Finish

Product Application

1. Residential building,school,hospital,prefab house,office, hotel,

public construction,entertainment place.

2. Wall/exterior wall/interior wall/super high wall/abnormity wall, roof,floor,pipe,

fire well,equipment partiton

Product Parameters

Product Specification

| Length | Width | Thickness |

| 2270mm 2440mm | 610mm | 60mm |

| 75mm | ||

| 90mm | ||

| 100mm | ||

| 120mm | ||

| 150mm |

Technical Index

| Item | Testing Indexes | |||||

| Model (Thinkness/mm) | 60mm | 75mm | 90mm | 120mm | 150mm | |

| 1 | Anti-impact Capacity [Standard sandbags/times] | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 |

| 2 | Anti-bending Damage Load [times over deadweight] | ≥3.0 | ≥3.0 | ≥3.0 | ≥5.0 | ≥5.0 |

| 3 | Compressive Stregth [Mpa] | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 |

| 4 | Softening Coefficient | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 |

| 5 | Surface Density [kg/] | ≤70 | ≤70 | ≤90 | ≤110 | ≤110 |

| 6 | Moisture Rate [%] | ≤10 | ≤10 | ≤10 | ≤8 | ≤8 |

| 7 | Drying Shrinkage Value [mm/m] | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| 8 | Hang Force [N] | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 |

| 9 | Sound Insulation Capacity In the Air[dB] | ≥35 | ≥35 | ≥40 | ≥45 | ≥50 |

| 10 | Fire Endurance [H] | ≥1.5 | ≥1.5 | ≥2.5 | ≥3.0 | ≥4.5 |

| 11 | Heat Transfer Coefficient [W/m2.k] | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| 12 | Inner Radiation Index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 13 | Outer Radiation Index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

Loading Information

| Items(mm) | Single(piece) | Load by 20'GP | Load by 40'GP | ||||||

| m³ | Kg/pcs | Kg/m2 | Qty(pcs) | m2 | Tons | Qty(pcs) | m2 | Tons | |

| 2270×610×60 | 0.08 | 47 | 34 | 313 | 433 | 15 | 525 | 727 | 26 |

| 2270×610×75 | 0.10 | 67 | 48 | 252 | 349 | 17 | 364 | 504 | 26 |

| 2270×610×90 | 0.12 | 77 | 56 | 207 | 287 | 16 | 322 | 446 | 26 |

| 2270×610×100 | 0.14 | 87 | 63 | 189 | 262 | 18 | 280 | 388 | 26 |

| 2270×610×120 | 0.17 | 98 | 71 | 162 | 224 | 16 | 252 | 349 | 26 |

| 2270×610×150 | 0.21 | 147 | 106 | 126 | 174 | 18 | 147 | 204 | 26 |

| 2440×610×60 | 0.09 | 60 | 40 | 240 | 357 | 15 | 420 | 625 | 26 |

| 2440×610×75 | 0.11 | 80 | 54 | 204 | 304 | 17 | 308 | 458 | 26 |

| 2440×610×90 | 0.13 | 90 | 60 | 168 | 250 | 16 | 336 | 500 | 26 |

| 2440×610×100 | 0.15 | 100 | 67 | 144 | 214 | 15 | 240 | 357 | 26 |

| 2440×610×120 | 0.18 | 110 | 74 | 108 | 161 | 12 | 216 | 321 | 26 |

| 2440×610×150 | 0.22 | 160 | 107 | 78 | 116 | 16 | 156 | 232 | 26 |

Installation

- Set line:set line and carry panel in position.

- Saw panel:use hand-hold eletrict saw to cut freely.

- Sizing:sizing cement on tenon side of two panels then spread ploymer mortar on one tenon.

- Installation:carry panel prepared to be installed panel.

- Plant bar in wall and pillar:dry one hold in the original pillar or wall and fix panel by one steel bar.

- Corret and fix:use one guiding ruler to check and level correction.

- Plant bar in structure beam:drill one hole in structure beam and plant one reversed 7 type shaped steel bar to fix with wall panel.

- Plant bar in floor:dirll one hole in floor and panlt 7 types shaped steel bar to fix with wall panel.

- Plant bar between wall panel:plant one 200mm length steel bar in the angle or 45 degree to fix between two panels.

- Install electric wire and switch:set lines on the place required to be settled with concealed wire and switch box.

- Grout and fill slurry:fill and handle corrected wall panel with ploymer mortar.

- Scrapping ash and sticking anti-crack cloth,coating:stick anti-crack cloth and brush coating after grouting slurry.

About Us

In the trend of low-carbon and energy-saving in domestic, ZJT is on a mission environmental protection, and actively promoting the development and popularization of green building materials. The composition of the materials of ZJT energy-saving wall panel strictly implements national GB6566-2001Building Materials Radionuclide Limited standard, which belong to the main of the radioactive building materials and a kind of decoration materials, 100% do not contain harmful substances in humans, and in high temperature combustion state, the release of excessive part also can be operated in an efficient range so it has no direct threat to human.

Customers' satisfication will be the best compliment for us!

Our capabilities speak for us!

You can always truth us!

FAQ

1. Q:How about your packing?

A:Free packing: we use normal pallet and packing belt for panels.

- Standard exporting packing:good pallet,pearl wool,corner protective paper,packing belt,plastic thin film.

- Packing size: 2270/S440*610*(60-150)mm

2. Q:How about your loading?

A:Our loading is normally 18 pallets per 20' container or according to clients' requirements.

3. Q:What is your MOQ?

A:A 20 feet container.

4. Q:How about your time of delivery?

A:It's about 15 days after receiving deposit.

5. Q:How can we get samples.

A:Our samples are free for your reference,you just need to pay for the freight.

6. Q:How about the payment terms?

A:30% T/T in advance T/T balance before delivery.

Contact Information

Contact us

Xiamen Zhongjingtai Building Materials Co., Ltd

Unit2A, Lianchang Building, No6-8 Huli District, Xiamen, China

Contact person:Jodie Huang

Mobile/ +86-13695041249

Website: zjteps.en.made-in-china.com