KRS calcium silicate product description:

Calcium silicate board products are made of SIO2 and CAO through high temperature and high pressure reaction, adding environmental protection fiber, new energy-saving insulation material without asbestos, the product can be long-term use in 650°-1050° high temperature environment, extend the service life of equipment.

preheaters and cyclone separators, decomposition kiln, tertiary air duct and cooler;

Nonferrous metallurygical industry:

Aluminum power calciner and electrolysis groove;

Petrochemical industry:

Splitting furnace, catalytic cracking furnace, petroleum pipeline, underground heat-flooding;

Metallurgical industry (steel plant):

Hot-rolling heat furnace, cool-rolling mill set, RH vacuum degassing furnace, smelters, hot deformation and heat treatment plants;

Power plant:

Preheat stove, pipe;

Glass industry:

Melting furnace and recuperator, annealing furnace and cooling channels.

CALCIUM SILICATE PROPERTIES & ADVANTAGES:

Good durability, can bear high temperature within the limit of continuous heat load.

Non-deformation within the temperature range.

Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

Light weight, high strength. It is the highest in these hard thermal insulation products.

Better durability, use for a long time without powder.

Construction with ordinary carpenter applicability, tools can be optional cut products.

Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

Fear water, but after drying also can be used.

Product Paramenters:

Product packaging:

cartons+wooden pallet or as per customer's request. The neutral carton packing or OEM.

The order will be shipped within 15 days after confirmation

Terms of payment: T/T, 30% deposit, the remaining 70% will be paid before shipment.

KRS NEW MATERIAL CO., LTD

KRS new material Co., Ltd is engaged in refractory and insulation material for about 20 years and had a good reputation among customers all over the world.

The main products of the company are high temperature resistant calcium silicate heat insulation products, ceramic fiber products,perlite product ,refractory brick,rock wool and other thermal insulation refractory materials.

Products are widely used in the construction of urban heat network and the heat insulation of various kinds of kiln and pipeline in metallurgy, petroleum, chemical, cement, electronics, machinery, ceramics, glass, natural gas and other industries.

Other specifications can be customized according to customer requirements.

Water repellent products can be customized.

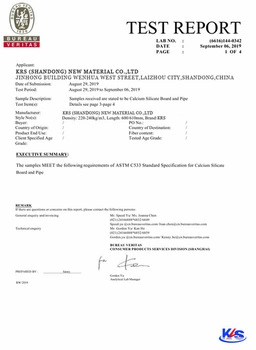

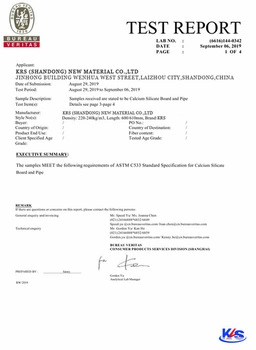

Certifications:

FAQ

1. Are you manufacturer or trade Company?

We are a manufacturer, and engaged in the production of refractory insulation materials for more than 20 years of history, enjoy a good reputation among customers around the world.

2.Which port can you support?

Qingdao port or TianJin port.If the destination port is provided, we can give you the quotation of CFR and CIF for your reference.

3.What's your Minimum order quantity(MOQ) of your product?

Most customers choose 1x20"GP as trial order. Small orders are also accepted

4.Can we visit your company?

Yes, for sure, you are welcome to visit our company.

5.We need samples. Can you provide samples for confirmation?Samples can be provided for confirmation, but we do not bear the cost of mailing.

6.Contact information

VIC Zhang

Calcium silicate board products are made of SIO2 and CAO through high temperature and high pressure reaction, adding environmental protection fiber, new energy-saving insulation material without asbestos, the product can be long-term use in 650°-1050° high temperature environment, extend the service life of equipment.

Application of KRS calcium silicate:

Cement industry:preheaters and cyclone separators, decomposition kiln, tertiary air duct and cooler;

Nonferrous metallurygical industry:

Aluminum power calciner and electrolysis groove;

Petrochemical industry:

Splitting furnace, catalytic cracking furnace, petroleum pipeline, underground heat-flooding;

Metallurgical industry (steel plant):

Hot-rolling heat furnace, cool-rolling mill set, RH vacuum degassing furnace, smelters, hot deformation and heat treatment plants;

Power plant:

Preheat stove, pipe;

Glass industry:

Melting furnace and recuperator, annealing furnace and cooling channels.

CALCIUM SILICATE PROPERTIES & ADVANTAGES:

Good durability, can bear high temperature within the limit of continuous heat load.

Non-deformation within the temperature range.

Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

Light weight, high strength. It is the highest in these hard thermal insulation products.

Better durability, use for a long time without powder.

Construction with ordinary carpenter applicability, tools can be optional cut products.

Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

Fear water, but after drying also can be used.

Product Paramenters:

| Calcium silicate board index | ||||||

| Items | Unit | KRS-A | KRS-B | KRS-C | KRS-D | |

| Density | Kg/m3 | 220±10% | 220±10% | 250±10% | 850±10% | |

| Pressure Strength | Mpa | ≥0.6 | ≥0.62 | ≥0.72 | ≥17 | |

| Flexural Strength | Mpa | ≥0.35 | ≥0.38 | ≥0.41 | ≥8 | |

| Thermal Conductivity | 100ºC | W/(M.K) | ≤0.055 | ≤0.053 | ≤0.059 | ≤0.095 |

| 200ºC | ≤0.067 | ≤0.064 | ≤0.068 | ≤0.12 | ||

| 400ºC | ≤0.078 | ≤0.072 | ≤0.079 | ≤0.14 | ||

| 800ºC | // | ≤0.171 | ≤0.193 | ≤0.25 | ||

| Temp.Limit | ºC | 650 | 1050 | 1050 | 1000 | |

| Linear Shrinkage | % | ≤2 | ≤2 | ≤2 | ≤2 | |

| Water repellent products can be customized | ||||||

| Calcium Silicate Board Size | ||

| Temperature | Size | |

| Length*Width(MM) | Thickness(MM) | |

| 650 or 1050 | 400*250 | 25-150 |

| 600*300 | 25-150 | |

| 600*150 | 25-150 | |

| 610*150 | 25-150 | |

| 500*500 | 25-130 | |

| 1050 | 600*600 | 25-130 |

| 1000*500 | 25-130 | |

| 1200*600 | 25-130 | |

| 1000*1000 | 25-130 | |

| 1200*1200 | 25-130 | |

| Other specifications can be customized according to customer requirements | ||

Product packaging:

Product packaging:

cartons+wooden pallet or as per customer's request. The neutral carton packing or OEM.

Lead time and payment terms:

The order will be shipped within 15 days after confirmation

Terms of payment: T/T, 30% deposit, the remaining 70% will be paid before shipment.

KRS NEW MATERIAL CO., LTD

KRS new material Co., Ltd is engaged in refractory and insulation material for about 20 years and had a good reputation among customers all over the world.

The main products of the company are high temperature resistant calcium silicate heat insulation products, ceramic fiber products,perlite product ,refractory brick,rock wool and other thermal insulation refractory materials.

Products are widely used in the construction of urban heat network and the heat insulation of various kinds of kiln and pipeline in metallurgy, petroleum, chemical, cement, electronics, machinery, ceramics, glass, natural gas and other industries.

Other specifications can be customized according to customer requirements.

Water repellent products can be customized.

Certifications:

FAQ

1. Are you manufacturer or trade Company?

We are a manufacturer, and engaged in the production of refractory insulation materials for more than 20 years of history, enjoy a good reputation among customers around the world.

2.Which port can you support?

Qingdao port or TianJin port.If the destination port is provided, we can give you the quotation of CFR and CIF for your reference.

3.What's your Minimum order quantity(MOQ) of your product?

Most customers choose 1x20"GP as trial order. Small orders are also accepted

4.Can we visit your company?

Yes, for sure, you are welcome to visit our company.

5.We need samples. Can you provide samples for confirmation?Samples can be provided for confirmation, but we do not bear the cost of mailing.

6.Contact information

VIC Zhang