Tile backer board (Extruded polystyrene),(Insulation foam board)

1.Description

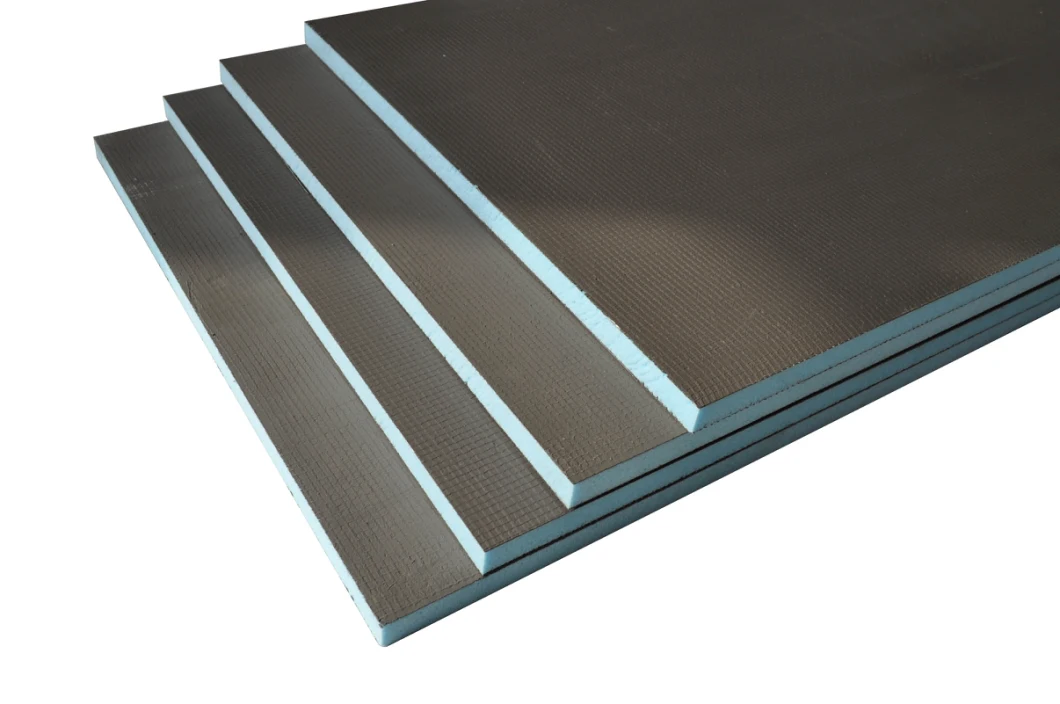

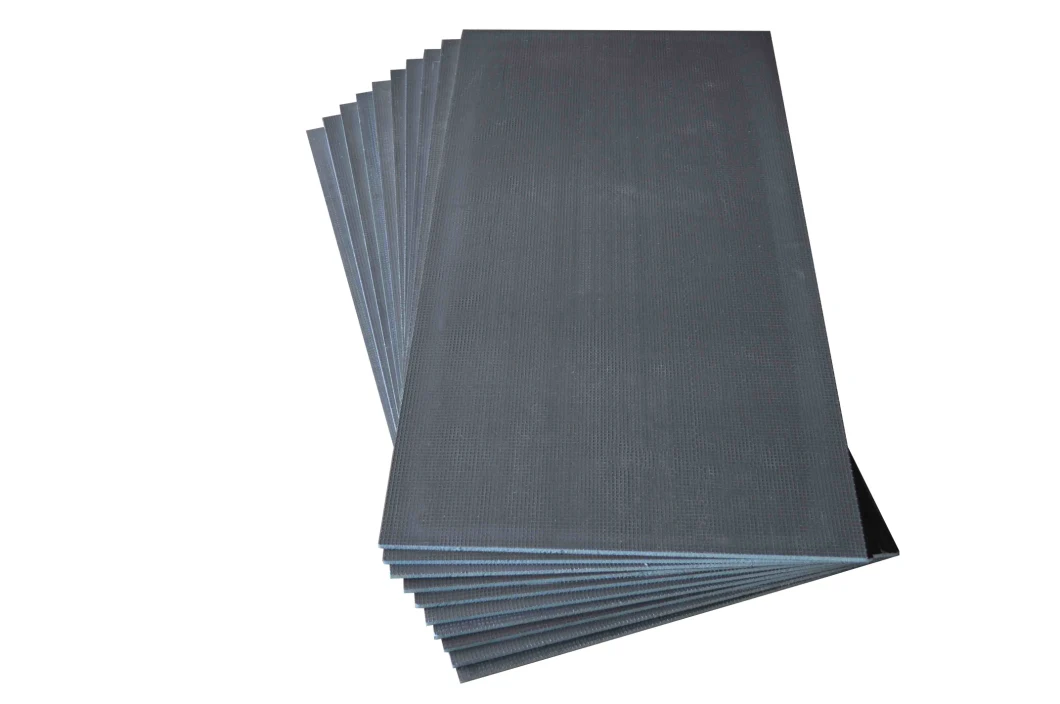

Product appearance XPS Tile Backer Board Brands Underfloor Heating Insulation Board: The boards have straight edges.

The color of the surface is grey and the core material is light blue.

Tile Backer Board consists of a blue core made from extruded polystyrene rigid foam.

1. Width: 600mm / 900mm / 1200mm

2. Length: 1200mm-3000mm(or any)

3. Thickness: 10-150mm

4. Density:28-55 kg/m3

5. Application:construction materials

6. Usage:water proof for Waterroom Wall & Floor,waterproof and insulation

7. Package: 1200*600*10mm xps tile backer board:10psc/Per carton

2.Usage:

1. As a watertight layer on walls and floors in wet rooms and bathrooms.

2. As an insulation layer under floor heating to avoid heat loss.

3. As partition walls in wood or steel frames.

4. As Substitute for gypsum board and firbercement board; insulation and waterproof;

It is lighter so it is very easy to install.

5. As enclosures for bathtubs, water pipes, etc.

6. It can be easy formed to be shelves, washbasins, shower benches and soap boxes.

7. Combining with curved/shape able boards, kinds of decorative models can be made with your infinite creativity.

Density | Kg/m3 | 31~50 |

Thermal conductivity, 90 days, 10°C | W/mK | 0.027~0.03 |

Compressive strength at 10% deflection or yield, (vertical) | kPa | ≥250 |

Tensile strength | kPa | ≥250 |

Water absorption | Vol-% | <=1.00% |

Capillarity | nil | nil |

Coefficient of linear thermal expansion | mm/mK | 0.07 |

Temperature limits | °C | -50°C, +75°C |

3. Benifite:

1. Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

2. Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

3. Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

4. Lightweight: volume optimization and easy to handle

5. Resistance to deformation

6. Resistance to impact

7. Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendly

8. Recyclable: Polyfoam can be 100% recycled

Working temperature range XPS Tile Backer Board Brands Underfloor Heating Insulation Board: 50 to +80 °C

Standard dimensions and weight XPS Tile Backer Board Brands Underfloor Heating Insulation Board:

Thickness(mm) | Weight(kg/m²) | Length by width(mm*mm) |

6 | 2,7 | 1200 x 600 |

10 | 2,9 | 1250 x 600 |

12 | 3,0 | 2500 x 600 |

20 | 3.1 | 2500 x 600 |

30 | 3,3 | 2500 x 600 |

50 | 4,2 | 2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to Fire:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

4.Applications:

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

Other questions? Please feel free to find my contact info below, I am very pleased to help you with any questions!

Arne Liu

Sales maneger

Address:Floor 17th, No.4 Building, Zhuyu International Commercial Center, No.9, Shouti South Road,Haidian District, Beijing 100048, China

Website:cnbmjacky.en.made-in-china.com,cnbmjacky.en.made-in-china.com